En-Masse Conveying & Elevating

MoveMaster®The Mechanics of

En-Masse Conveying & Elevating

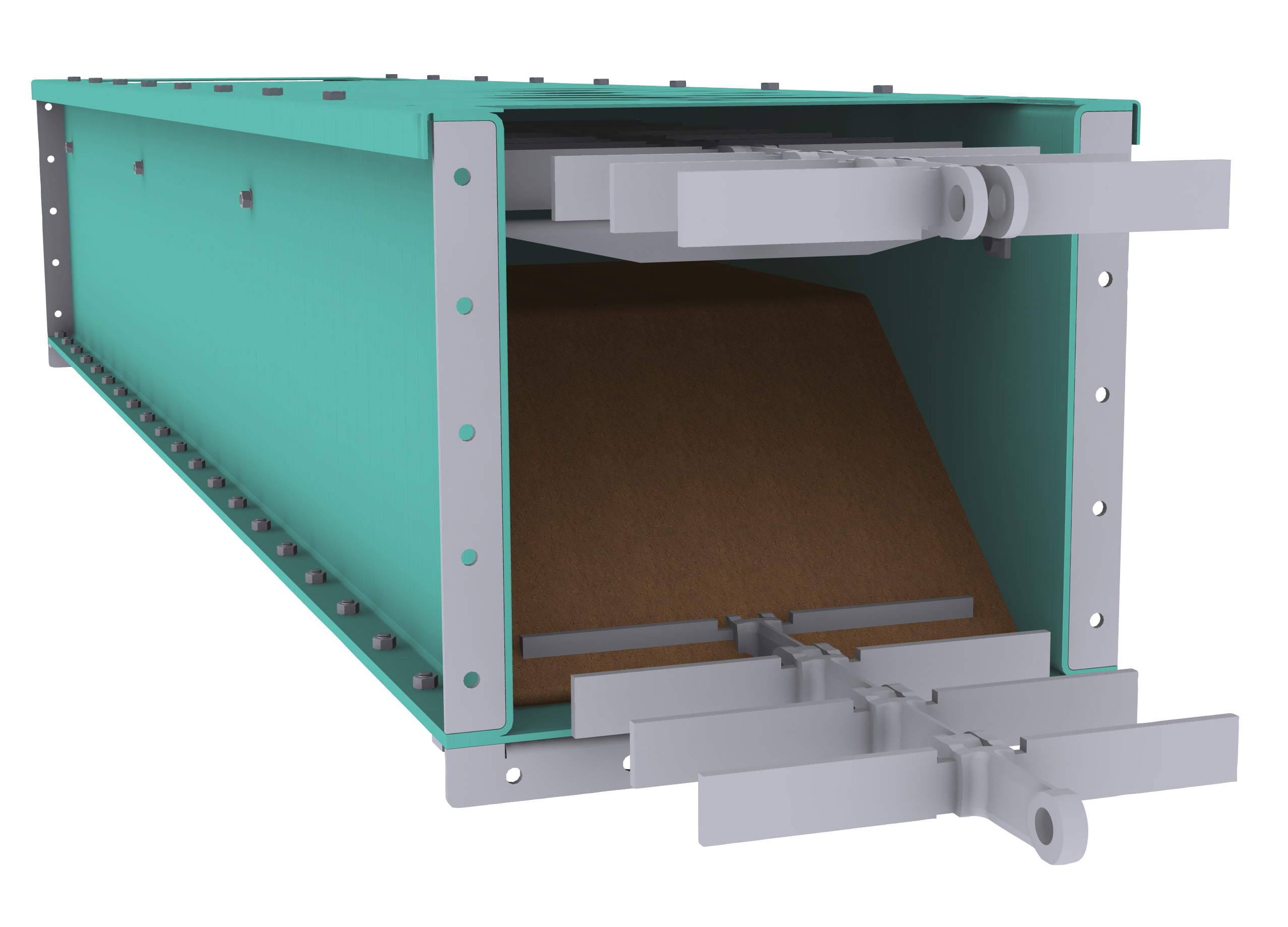

En-Masse movement is the term used to describe the unique method of conveying bulk materials smoothly, gently and economically.

Material is induced to move like a liquid through a slender dust tight steel casing, horizontally, on an inclined plane, vertically and around bends.

The conveyor feeds itself at any point with a uniform load. The skeletal flight configuration induces the material to flow in a solid, placid column.

There is no internal disturbance or pressure on the material and the load can be discharged at any opening, where it is permitted to fall away from the flights.

The conveyor is not a scraper conveyor. There is no dragging or scraping action, material simply moves forward in a solid placid column, ‘En-Masse’

MoveMaster® – En-Masse Conveying in Action

When the chain is buried in the material, its motion induces the entire mass to move gently forward in a uniform, solid column. There is no material dragging, particle tumbling, or rolling.

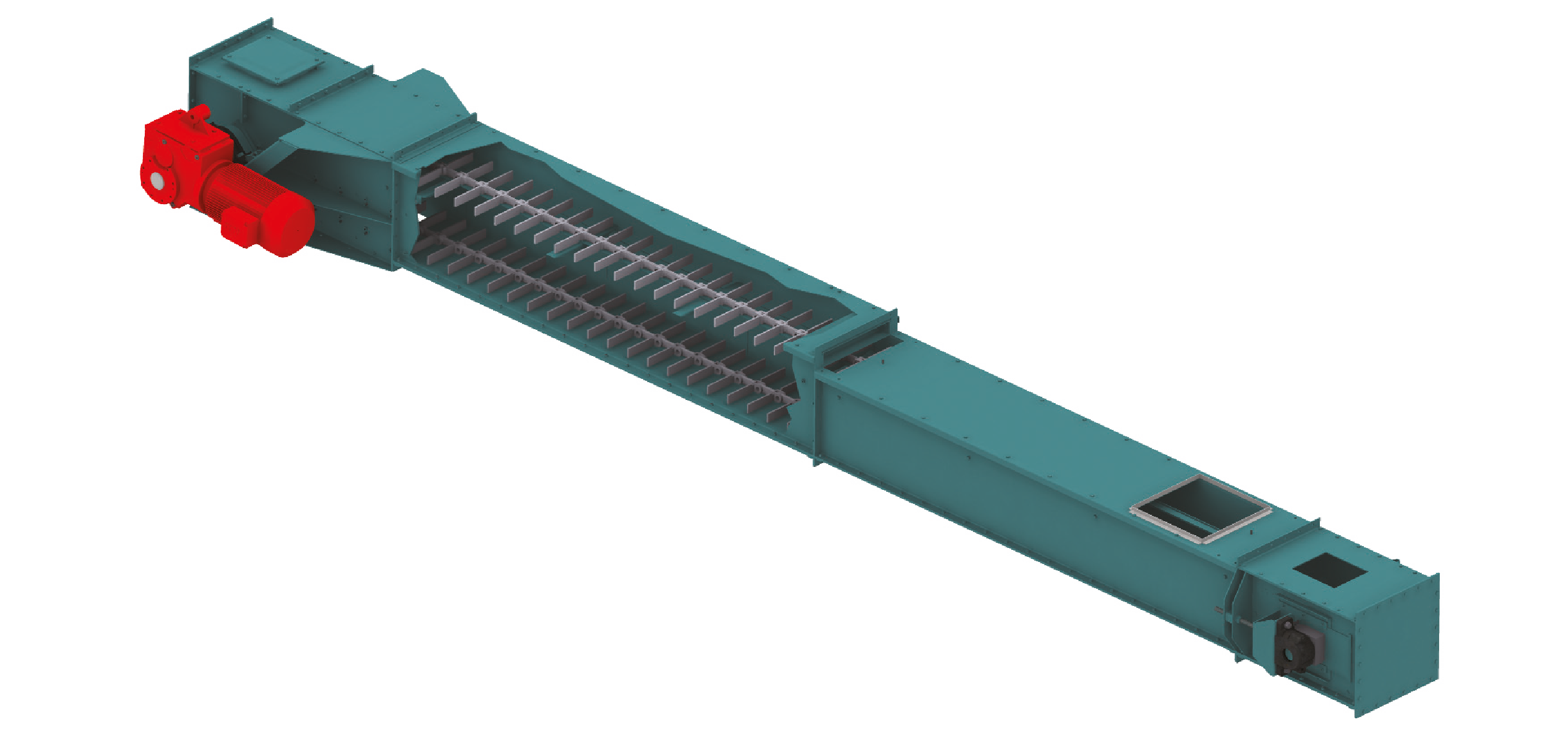

MoveMaster® en-masse conveying systems are manufactured in a standard range of sizes from 200mm wide upwards, designed to meet a wide variety of application needs and layout requirements.

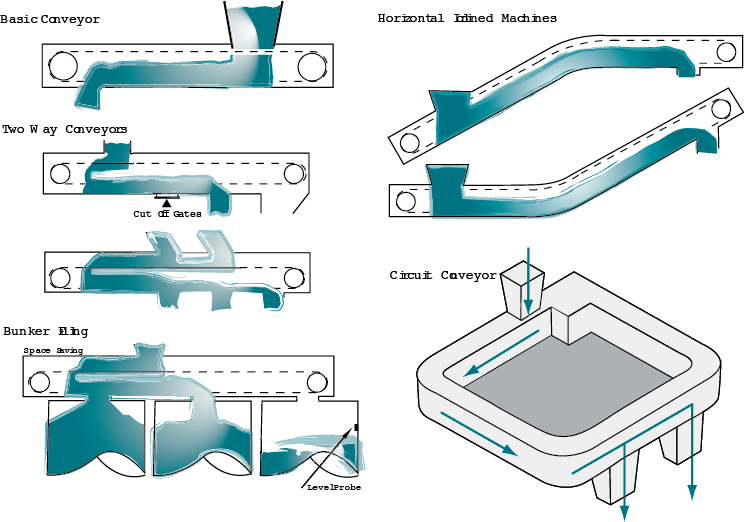

Popular

Conveying Arrangements

Facts and figures

• Totally enclosed casing

• Integral or independently mounted drives

• Safety choke detector

• Single or multiple outlets

• Schenck Process high strength conveyor chain

• Single or multiple inlets

• ‘RoCon’ underspeed safety control switch

MoveMaster® Chain Movement

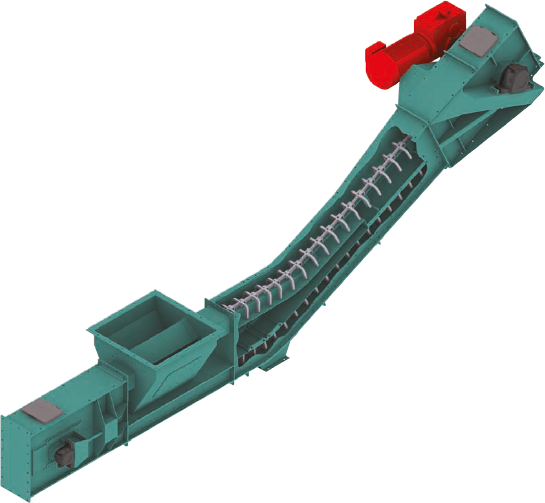

Movement of the chain when buried in the material will induce the whole mass to move forward gently in a solid column. The Eleveyor design permits the column of material to be moved vertically or on an inclined plane. Eleveyors are manufactured in a standard range of sizes from 200mm wide upwards, which enables them to meet every requirement.

Popular

Elevating Arrangements

Features and Benefits

• Simple chain tensioning

• Hoppered inlet

• Redler high strength chain

• Integral or independently mounted drives

The Benefits of

MoveMaster® En-Masse Handling

Cost Effective:

Capital costs prove very competitive with other forms of handling equipment, thus giving quicker ‘payback period’.

Power Running Costs significantly lower than most other forms of equipment, i.e they can be as low as 1/10 of dense phase conveying.

Low Cost Maintenance. Heavy duty rigid construction in simple modules, high strength chain, choke detectors, overload and underspeed switches all ensure easy maintenance at infrequent intervals.

Labour Saving:

Manual to fully automatic control of single or multiple machine systems provided by proven basic control systems.

No specialised maintenance staff required.

Environmentally Acceptable:

Totally enclosed machines and transfer points of dust-tight and weatherproof construction.

Safe as all moving parts are totally enclosed.

Versatile:

Specialised features of ‘En-Masse’equipment offer versatility to plant layout.

Handles virtually all types of dry bulk products.

Size:

Size and duty comparison with alternative forms

of handling equipment.

Gentle Handling:

Materials moves ‘En-Masse’ slowly in a solid placid column with the conveying elements; thus degradation is virtually eliminated.

Chain design permits material column to change direction through bends, without degradation.

Proven:

Over 90 years experience of handling hundreds of bulk materials worldwide within a wide range of industries.

Extend the life of your MoveMaster®

Want to extend the life of your material handling equipment?

Aftermarket Service Programme

Explore our Aftermarket Service programme — now including Redler Plus, offering service and retro-fitting for third-party en-masse conveyors.

Address

Redler Limited

Unit 102 Stonehouse Business Park,

Sperry Way, Stonehouse, Gloucestershire, GL10 3UT, United Kingdom

Phone

T: +44 (0) 1453 704300